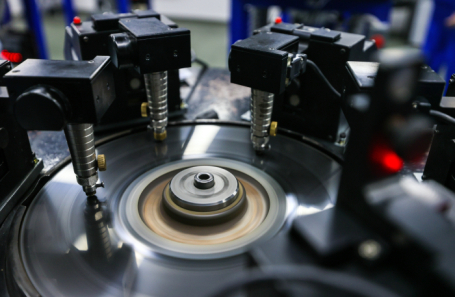

The list of items prohibited from entering Russia has been revised by Japan. Among the newly included items are computer-controlled lathes and milling machines. Officials in Tokyo believe this machinery is utilized in the manufacturing of arms.

In the updated document listing Japanese products banned from being imported into Russia, milling machines, communication and electronic apparatus, and items utilized in the production of electronic semiconductors are also included.

Many Japanese machine producers have already exited the Russian market, officially ceasing all shipments to the country. They have also discontinued servicing equipment present in Russia. However, Japanese industrial machines are still finding their way into Russia, including spare parts. The same applies to machinery from American and European manufacturers, but these shipments are now unofficial.

According to Stanislav Shepelev, who heads the Robotics Design Bureau at MIET:

“The sanctions led to supply constraints, disruptions in logistics chains, and equipment-related challenges. This also impacted spare parts, especially from countries with strained relations. Looking to other sources or routes for supplies can offer some solutions. Companies that have left Russia and are deemed unfriendly have likely halted software updates. Working with alternative software might become necessary for certain equipment, some of which may require bypassing protections or changing the control system.”

“Promet,” a company specializing in safes and metal furniture, previously utilized Japanese machinery but has opted to switch. Alexey Petrov, the director of “Promet,” mentioned:

“We were influenced by the self-imposed restrictions on equipment supplies to Russia, pushing us to explore other options. We started to venture into machine tool construction and fabrication of bending equipment ourselves, prompted by a supplier’s refusal to provide or service existing equipment. Cheaper alternatives to Japanese and European machinery exist. These range from Turkish machines to equipment from China, which come at a significantly lower cost than their European counterparts. While there are alternatives to the ‘Japanese’ and ‘Europeans,’ unfortunately, they lack alternative markets.”

There are manufacturing facilities that do not require the precision or high cost associated with Japanese machinery. This sentiment was shared by Vadim Markelov, CEO of the Karelian enterprise MB-Barbell, in an interview with Business FM:

“As manufacturers of sports equipment, we find Japanese machinery to be unnecessary. Instead, we recently acquired a batch of Russian-made machine tools from Tver, along with electronics, which have fully met our requirements. We just completed the installation process, and we are content with the quality of Russian manufacturing. For mass production, which is our focus, the quality of domestic equipment suffices. We sought the specific equipment in Turkey, which the domestic engineering sector lacks. We encountered no issues—it arrived, and we put it to use.”

Multiple websites within Russia offer a wide array of Japanese machinery, including those with computer numerical control (CNC). However, these sites do not provide pricing information. It remains unclear from where these machines are shipped and the duration of deliveries. Nonetheless, individuals seeking such equipment can conduct a search and potentially make a purchase.